Grinding Shot Manufacturer

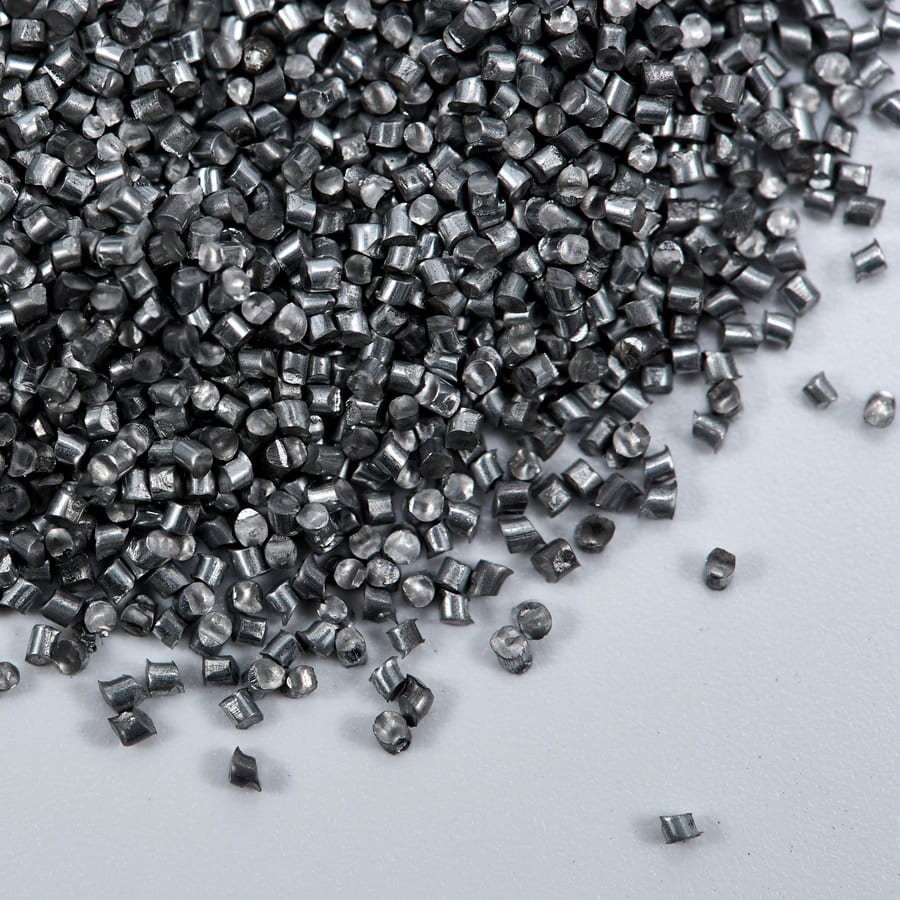

Grinding shot, also referred to as treated steel cut wire shot or conditioned/rounded steel cut wire, is a specially forged product designed for shot blasting applications.

It is produced by cutting high-manganese steel wires into cylindrical shapes using high-speed precision cutting equipment.

The cut wires are then processed through rounding machines, transforming them into grinding shots with uniform dimensions and smooth surfaces, ideal for consistent blasting performance.

Product Details

Steel Cut Wire Shot is manufactured by cutting high-quality steel wires into uniform granules. Depending on the production process, it can be supplied in two main shapes: cylindrical cut wire and spherical cut wire (rounded shot). Through advanced rounding technology, the cut edges are eliminated, producing a smooth and durable shot material.

Characteristics

High Hardness – Typically above 50 HRC, much harder than conventional cast steel shots, ensuring aggressive blasting performance.

Durable & Long Life – Uniform microstructure and excellent fatigue resistance provide a longer operational life.

Consistent Shape – Available in both cylindrical and spherical forms, offering stable blasting quality.

Size Range – Standard sizes from CW1.0mm to CW3.0mm, with customized sizes available upon request.

Product Specifications

| 名称 Name | 参数 Specification |

|---|---|

| 化学成分 Chemical composition |

C: 0.45–0.7% Mn: 0.3–1.3% Si: 0.15–1.35% S: ≤0.05% P: ≤0.04% |

| 平均硬度 Average hardness | HRC50 ±3 |

| 最小密度 Minimum density | ≥7.8 g/cm³ |

| 堆积密度 Stacking density | 4.5 g/cm³ |

| 金相组织 Metallurgical structure | Deformation troostite |

| 性能特点 Performance feature |

High hardness, good wear resistance, high cleaning efficiency, remarkable strengthening effect, stable composition and good workpiece treatment effect |

Product Applications

Grinding shots are forged to eliminate voids, cracks, and breakage, ensuring durability during use. In operation, their shape gradually wears down and becomes smaller. Once the size is reduced to less than 30% of the original, the shots are automatically removed by the dust removal and separation systems of the blasting machine, completing their service life cycle.

As a subcategory of steel wire cut shot, grinding steel shots are produced by cutting steel wire into cylinders with equal diameter and length, then rounding the sharp edges to form spherical particles. This process gives them the combined advantages of both cast steel shots and steel cut wire: uniform grinding, no damage to the workpiece, high wear resistance, and long service life. They are widely used in precision processing industries, especially for automotive and motorcycle parts, where they provide excellent surface finishing and strengthening results.

With a mature and standardized production process, grinding steel shots are free of internal pores and feature highly uniform particle sizes. Their short blasting cycle improves efficiency, while maintaining consistent quality. In industrial applications, they are ideal for components such as quenched gears, screws, springs, chains, stamping parts, stainless steel pieces, and other high-hardness workpieces. They effectively remove oxides, perform surface strengthening, achieve dust-free blasting, and highlight the metallic luster of the product.