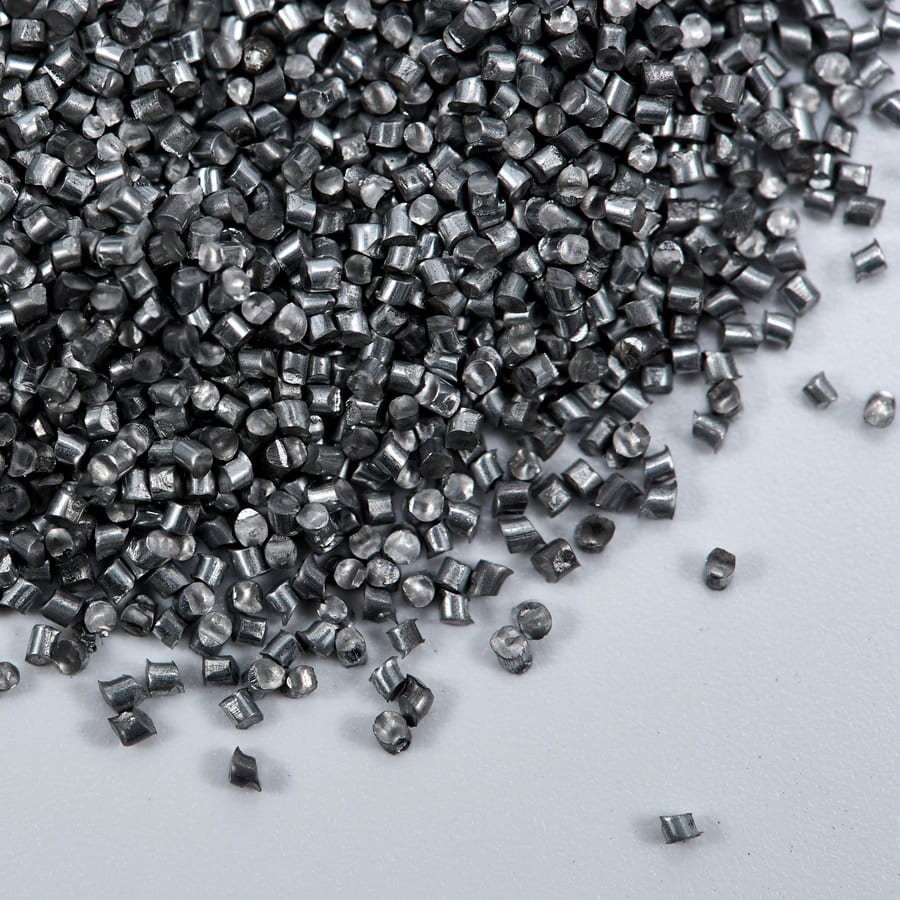

Low carbon steel shot is a versatile abrasive media widely used in surface treatment processes such as cleaning, descaling, deburring, and peening. Produced from a steel alloy with a carbon content typically below 0.2%, this composition gives it distinctive properties and broad industrial applications.

One of the main advantages of low carbon steel shot is its excellent ductility and toughness. Unlike harder and more brittle abrasives such as high-carbon steel or cast iron shot, low-carbon shot deforms on impact instead of shattering. This makes it especially suitable for treating delicate surfaces, including thin sheet metal, aluminum alloys, and non-ferrous components, where maintaining surface integrity and minimizing erosion are essential. Its energy-absorbing properties also reduce the risk of damaging the substrate.

Because of these characteristics, low carbon steel shot is the preferred abrasive for applications that require both a gentle approach and a smooth finish. Its combination of softness, durability, and resistance to fracture makes it indispensable in industries such as automotive, aerospace, and precision metal fabrication—where protecting the underlying material is as important as achieving effective cleaning and preparation.

Because of these characteristics, low carbon steel shot is the preferred abrasive for applications that require both a gentle approach and a smooth finish. Its combination of softness, durability, and resistance to fracture makes it indispensable in industries such as automotive, aerospace, and precision metal fabrication—where protecting the underlying material is as important as achieving effective cleaning and preparation.

Because of these characteristics, low carbon steel shot is the preferred abrasive for applications that require both a gentle approach and a smooth finish. Its combination of softness, durability, and resistance to fracture makes it indispensable in industries such as automotive, aerospace, and precision metal fabrication—where protecting the underlying material is as important as achieving effective cleaning and preparation.