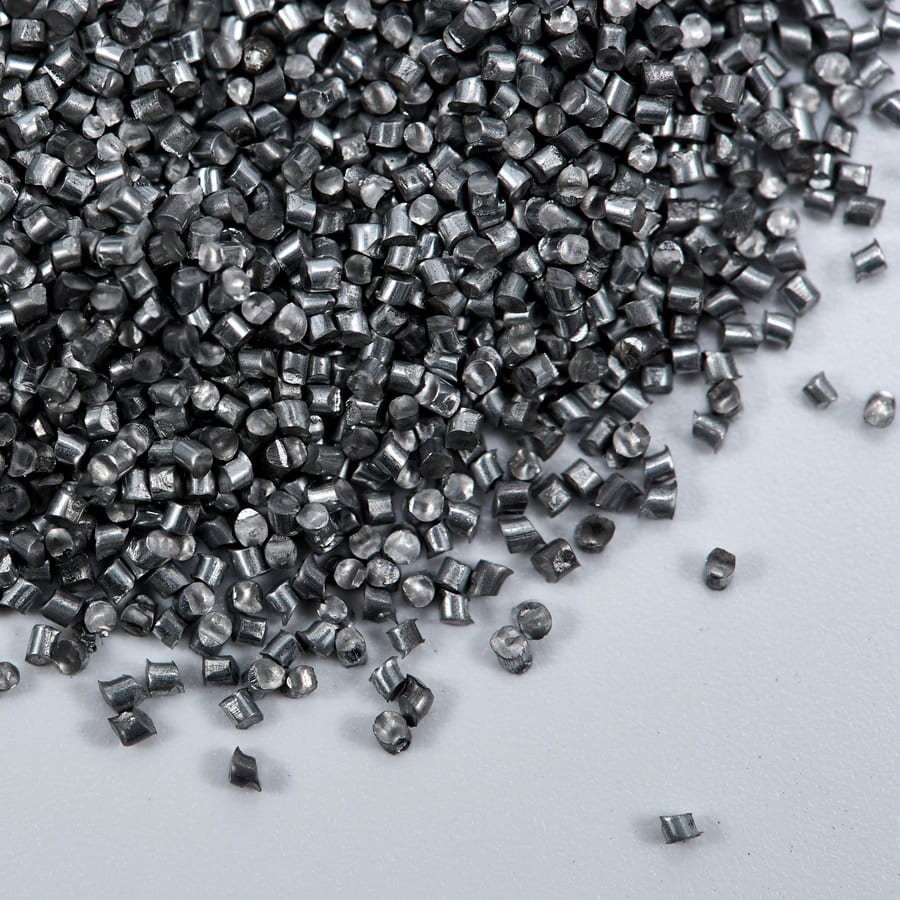

Low-carbon steel shot is an essential material in the field of metal surface treatment, playing a vital role in the global industrial supply chain. With a carbon content of ≤0.2%, it is widely applied in casting cleaning, surface strengthening, and coating pre-treatment. Its advantages—excellent toughness, long service life, and minimal wear on equipment—make it a preferred choice for many industries.

Professional low-carbon steel shot manufacturers ensure stable and reliable product performance through advanced production processes. Typical production steps include wire cutting, quenching and hardening, tempering, and precision sieving, which yield highly spherical abrasives with a hardness range of HRC 40–50. Leading producers often operate under ISO9001 quality management systems and supply products that comply with international standards such as SAE J827 and VDFI 8001.

Today, the world’s major producers are concentrated in Asia, Europe, and North America. Chinese manufacturers, leveraging scale advantages and cost efficiency, hold over 50% of the global market share. In regions such as Shandong and Jiangsu, leading enterprises achieve annual outputs exceeding 100,000 tons. Meanwhile, European manufacturers specialize in high-end, customized products—for example, ultra-fine low-carbon steel shot (S230–S330) used in aerospace applications.

When selecting a low-carbon steel shot supplier, industrial customers should focus on the following factors:

Consistency and stability of product quality

Environmentally responsible production capacity (e.g., dust control technologies)

Level of customization (particle size distribution and packaging solutions)

Logistics capabilities and after-sales technical support

With the global shift toward greener manufacturing, leading low-carbon steel shot manufacturers are actively adopting eco-friendly practices, including electric arc furnace steelmaking and wastewater recycling systems. These innovations not only reduce production costs but also deliver sustainable surface treatment solutions that meet increasingly strict environmental standards.