Steel Grit Manufacturer

We are dedicated to producing high-quality steel grit with meticulous care and advanced processes.

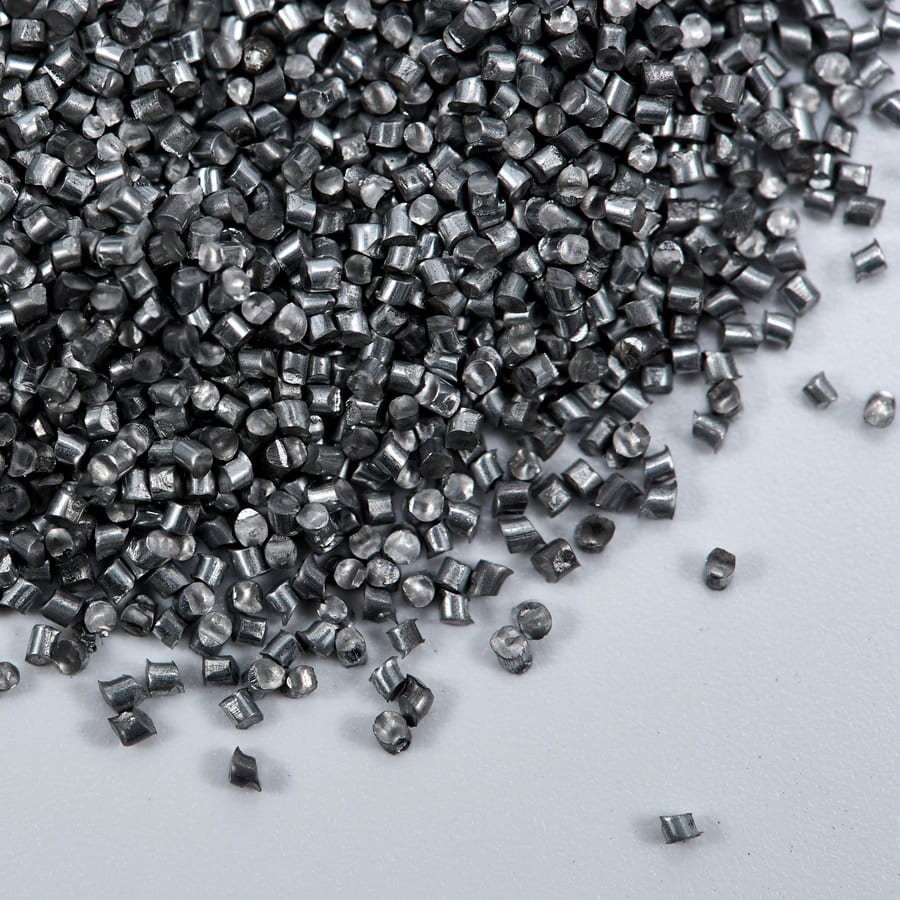

Product: Cast Steel Grit

Types: GP / GL / GH

Sizes: G12 – G120

All our steel grit is manufactured in accordance with SAE standards, covering GP, GL, and GH types in full size ranges from G12 to G120. Using premium raw materials and state-of-the-art techniques—such as centrifugation, tempering, double quenching, and upgraded screening—our products have gained strong recognition worldwide. In addition, we also offer customized options for size and hardness to meet specific customer needs.

Product Details

Steel grit is produced by crushing high-quality steel shot, ensuring excellent overall quality. With nearly 20 years of manufacturing experience and strong teamwork, we have continuously improved our processes to deliver higher value-added products to our customers.

We supply steel grit in a wide range of sizes, including G12, G14, G16, G18, G20, G25, G40, G50, G80, and G120. According to different hardness levels, three types are available:

GP: 40–50 HRC

GL: 50–60 HRC

GH: 60–66 HRC

Product Specifications

| 名称 Name | 钢砂 Bearing steel grit |

|---|---|

| 化学成分 Chemical composition |

C: 0.45–0.7% Mn: 0.3–1.3% Si: 0.15–0.3% S: ≤0.05% P: ≤0.04% |

| 硬度 Hardness |

GP: 42–52HRC GL: 53–60HRC GH: 60–64HRC |

| 密度 Density | ≥7.8 g/cm³ |

| 外观 External form | 扁平、棱角多、棱角锋利 Flat shape, much angular, sharp angular |

| 金相组织 Metallurgical structure | 均一回火索氏体 Homogeneous tempered sorbite |

| 性能特点 Performance feature |

轴承钢材质内含有 Cr、Mo 稀有元素,形成稳定良好的内在组织。轴承钢砂反应出高稳定性、高耐磨性,是高碳钢钢丸、低碳钢钢砂寿命的 2.5 倍以上。 Bearing steel contains rare elements such as Cr and Mo, forming a stable and good internal structure. Bearing steel grit has high stability and wear resistance, which is more than 2.5 times of the life of high carbon cast steel shot and low carbon cast steel grit. |

| 目数 Mesh | mm | 2.5 | 2.0 | 1.7 | 1.4 | 1.2 | 1.0 | 0.7 | 0.4 | 0.3 | 0.2 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 2.80 | all pass | |||||||||

| 8 | 2.36 | all pass | |||||||||

| 10 | 2.00 | 80%min | all pass | ||||||||

| 12 | 1.70 | 90%min | 80%min | all pass | |||||||

| 13 | 1.40 | 90%min | 80%min | all pass | |||||||

| 16 | 1.18 | 90%min | 75%min | all pass | |||||||

| 18 | 1.00 | 85%min | 75%min | all pass | |||||||

| 20 | 0.850 | ||||||||||

| 25 | 0.710 | 85%min | 70%min | all pass | |||||||

| 30 | 0.600 | ||||||||||

| 35 | 0.500 | ||||||||||

| 40 | 0.425 | 80%min | 70%min | all pass | |||||||

| 45 | 0.355 | ||||||||||

| 50 | 0.300 | 80%min | 65%min | all pass | |||||||

| 80 | 0.180 | 75%min | 65%min | ||||||||

| 120 | 0.125 | 75%min | 60%min | ||||||||

| 200 | 0.075 | 70%min | |||||||||

| 325 | 0.045 | ||||||||||

| SAE J444 | G-10 | G-12 | G-14 | G-16 | G-18 | G-25 | G-40 | G-50 | G-80 | G-120 | |

Product Applications

In shipyards, hull surfaces are treated with primary and secondary sandblasting for effective rust removal and cleaning. Similarly, the pretreatment line for hull steel plates also involves sandblasting and rust removal to ensure a clean and prepared surface.

For steel structures, section steel, steel plates, and accessories are processed by continuous shot blasting machines. This ensures the required cleanliness and surface roughness, providing an ideal foundation for subsequent processes such as painting and coating. To help customers minimize production costs and reduce abrasive consumption, we focus on supplying high-quality, cost-effective steel shots.

Applications:

Rust Removal: shot blasting, shot peening, casting rust removal, forging rust removal, steel plate rust removal, H-beam rust removal, and steel structure rust removal.

Shot Blasting: section steel, ship plates, steel plates, and other steel components.

Pretreatment: coating pretreatment, surface pretreatment, ship plate pretreatment, steel plate pretreatment, and structural steel pretreatment.