Low Carbon Steel Shots Manufacturer

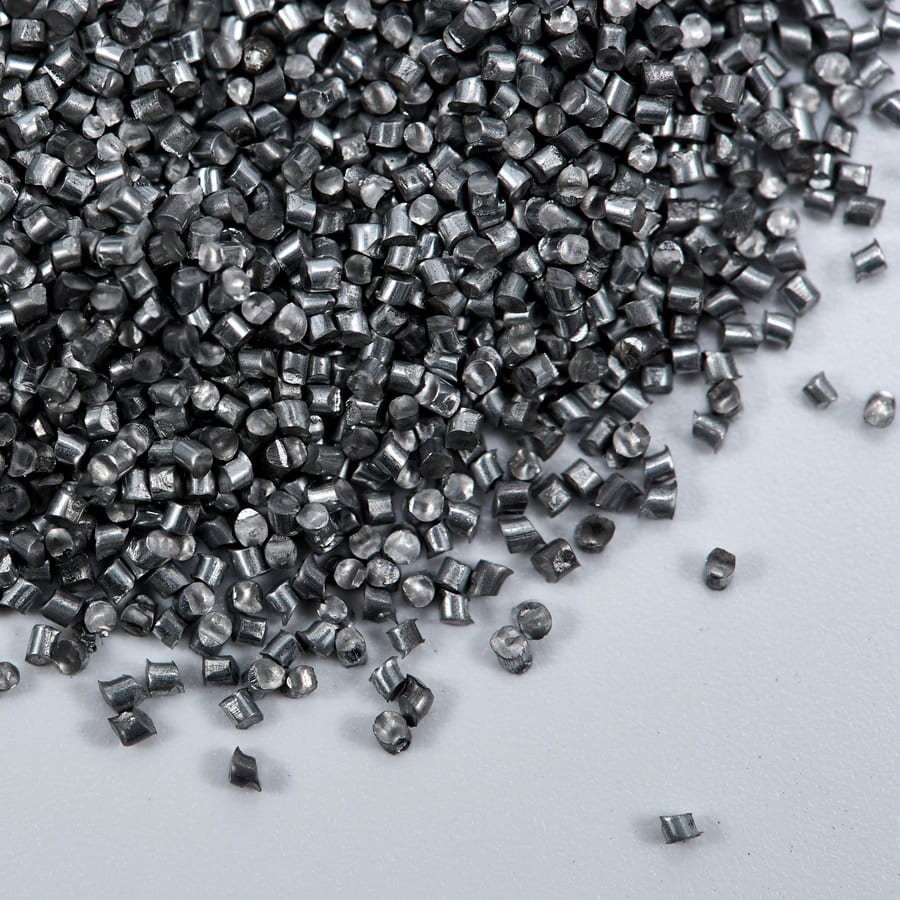

Low Carbon Steel Shots (S110–S930)

We offer low carbon steel shots ranging from S110 to S930. With a carbon content below 0.15% and a bainite structure, they deliver superior performance compared to high carbon steel shots. Their fatigue life is approximately 70% longer, ensuring greater durability and stability.

Our steel shots are manufactured with utmost precision and dedication. Unlike high carbon steel shots, which often suffer from defects such as cracks and blowholes, our low carbon steel shots are developed to eliminate these weaknesses. When compared in terms of microstructure, fatigue life, and overall performance, low carbon steel shots stand out as the better choice.

Product Details

Low Carbon Steel Shots

Low carbon steel shots, with a carbon content of less than 0.15%, feature a bainite structure. To guarantee consistent performance, we use only premium special steel materials as raw inputs. This ensures excellent quality from the very start.

Backed by a strong R&D team and advanced production lines, we provide customers with stable, high-quality products. Our professional management of the entire process also allows us to maintain competitive pricing, helping customers reduce costs and improve market competitiveness.

Microstructure as Quality Benchmark

The microstructure is a key indicator in evaluating the quality of steel shots. Here, we present microstructure comparisons between low carbon steel shots and high carbon steel shots.

Key advantages of low carbon steel shots:

Crack-free and defect-free surface

High tenacity

Superior fatigue life

Product Specifications

| 名称Name | 低碳钢丸 / 国标钢丸Low-carbon steel shot |

|---|---|

| 化学成分Chemical composition | 碳 C 0.1–0.2% 锰 Mn 0.5–1.2% 硅 Si 0.4–1.2% 硫 S ≤0.04% 磷 P ≤0.04% 铬 Cr ≤0.45% (max) 镍 Ni ≤0.013% (max) |

| 硬度Hardness | HV 390–530 (≈ HRC 39.8–51.1) |

| 密度Density | 7.4–7.6 g/cm³ |

| 外观External form |

• 气孔含量 < 10% / Air holes < 10% • 缺陷(连体、尖角、变形等)< 10% / Defective rate (agglomerates, sharp corners, deformity, etc.) < 10% |

| 金相组织Metallurgical structure | 均匀的回火马氏体或贝氏体 / Homogeneous tempered martensite or bainite |

| 性能特点Performance / Features |

产品在炼钢脱氧工艺中成分稳定,内外部缺陷少;韧性好、回弹效果佳,使用寿命通常高于高碳钢丸。 The product is deoxidized in the steel-making process, with stable composition and low defect rate; it offers good toughness and rebound, and typically lasts longer than high-carbon steel shot. |

| mesh | mm | SS-2.5 | SS-2.0 | SS-1.7 | SS-1.4 | SS-1.2 | SS-1.0 | SS-0.8 | SS-0.6 | SS-0.5 | SS-0.3 | SS-0.2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 2.80 | all pass | ||||||||||

| 8 | 2.36 | all pass | ||||||||||

| 10 | 2.00 | 85%min | all pass | all pass | ||||||||

| 12 | 1.70 | 97%min | 85%min | 5%max | all pass | |||||||

| 14 | 1.40 | 97%min | 85%min | 5%max | all pass | |||||||

| 16 | 1.18 | 97%min | 85%min | 5%max | all pass | |||||||

| 18 | 1.00 | 96%min | 85%min | 5%max | all pass | |||||||

| 20 | 0.850 | 96%min | 85%min | 10%max | all pass | |||||||

| 25 | 0.710 | 96%min | 85%min | 10%max | ||||||||

| 30 | 0.600 | 96%min | 85%min | all pass | ||||||||

| 35 | 0.500 | 97%min | 85%min | 10%max | ||||||||

| 40 | 0.425 | 97%min | all pass | |||||||||

| 45 | 0.355 | 80%min | 10%max | |||||||||

| 50 | 0.300 | 90%min | ||||||||||

| 80 | 0.180 | 80%min | ||||||||||

| 120 | 0.125 | 90%min | ||||||||||

| 200 | 0.075 | |||||||||||

| 325 | 0.045 | |||||||||||

| SAE | S-780 | S-660 | S-550 | S-460 | S-390 | S-330 | S-280 | S-230 | S-170 | S-110 | S-70 | |

Product Applications

Low carbon steel shots are widely used in surface treatment, cleaning, and strengthening processes across multiple industries. With their low carbon content (≤0.15%), bainite or martensite structure, and longer fatigue life, they are highly suitable for applications where durability and efficiency are required.

Main Applications:

Shipbuilding Industry – Hull plate cleaning, rust removal, and surface preparation before coating or painting.

Steel Structure Industry – Shot blasting of section steel, H-beams, pipes, and steel plates to achieve required surface roughness and cleanliness.

Automotive Manufacturing – Surface strengthening of automotive components, improving fatigue resistance and extending service life.

Foundry & Forging Industry – Removal of sand, rust, and oxide scale from castings and forgings.

Mechanical Engineering – Surface preparation for machinery parts, ensuring strong coating adhesion and improved wear resistance.

Pipeline & Oil Industry – Internal and external cleaning of steel pipes, tanks, and pressure vessels.

Pretreatment Lines – Steel plate and structural steel pretreatment before painting or galvanizing.