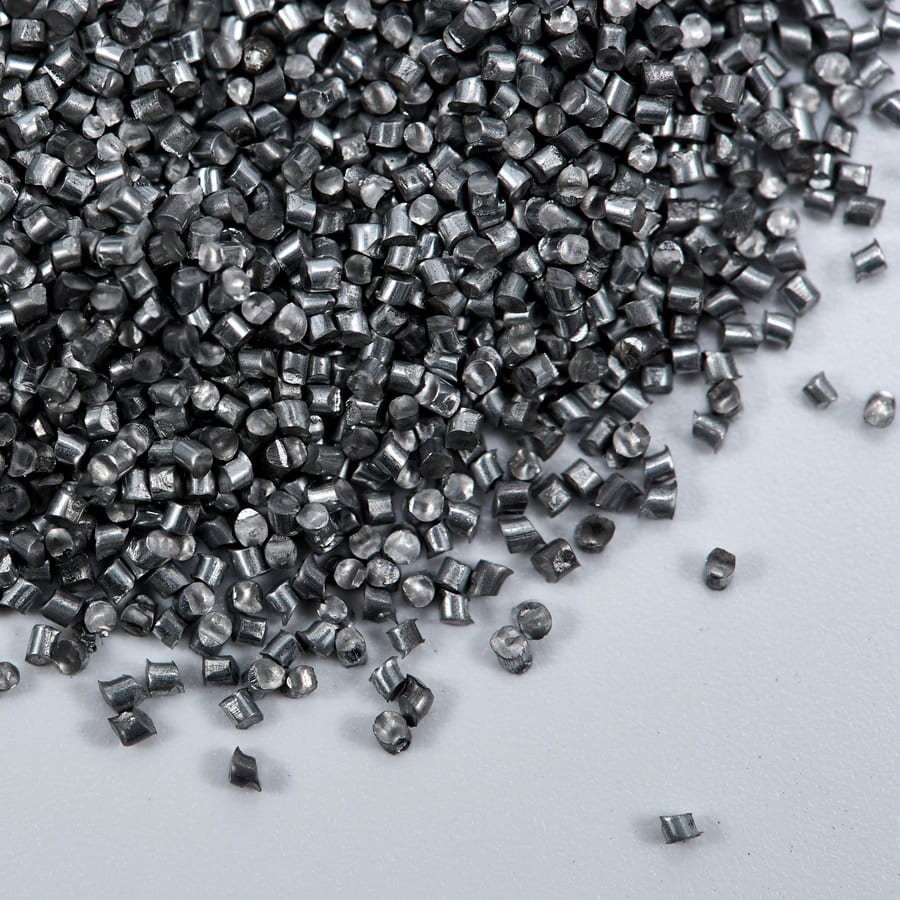

High Carbon Steel Shot Manufacturer

SAE standard high carbon steel shots, with a carbon content of 0.8–1.2, are manufactured using carefully selected, high-quality raw materials. We offer a complete range from S70, and our products are widely recognized and trusted by customers worldwide.

At our factory, we put our full dedication into every step of production, ensuring consistent quality and reliable performance.

We specialize in manufacturing and supplying the full range of high carbon steel shots — S70, S110, S130, S170, S230, S280, S330, S390, S460, S550, S660, S780, S930. All products are strictly produced in accordance with the latest SAE standards.

Product Details

Advantages of our production:

We forever using well-chosen raw materials, the best quality of metal scraps. And every time our lab inspect random samples from materials for final confirmation, by visual and test its chemical compositions etc.

All processing including melting in furnace, centrifugation, drying, tempering, quenching, screening and packing etc, we all manage and control well by our professional teams. Among these, our furnace is bigger one, 15mts capacity, it enable us to manufacture big quantity of products. And we have continuous tempering lines, robot automatic packaging lines etc. All above these ensure better service and quality to our worldwide customers.

Product Specifications

| 名称Name | 高碳钢丸High Carbon Steel Shot |

|---|---|

| 化学成分Chemical composition | 碳 C 0.8–1.2% 锰 Mn 0.35–1.2% 硅 Si ≥0.4% 硫 S ≤0.05% 磷 P ≤0.05% |

| 平均硬度Average hardness |

常规:40–50HRC 特殊:52–56HRC 特殊:56–60HRC |

| 硬度偏差Hardness deviation | The maximum deviation range is ±3.0HRC |

| 欧文寿命Ervin lifetime | 2200–2600次 |

| 金相组织Metallurgical structure |

均匀的回火马氏体或回火屈氏体 Uniform tempered martensite or tempered troostite |

| 密度Density | 7.4 g/cm³ |

| 堆积密度Stacking density | 4.4 g/cm³ |

| mesh | mm | SS-2.5 | SS-2.0 | SS-1.7 | SS-1.4 | SS-1.2 | SS-1.0 | SS-0.8 | SS-0.6 | SS-0.5 | SS-0.3 | SS-0.2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 2.80 | all pass | ||||||||||

| 8 | 2.36 | all pass | ||||||||||

| 10 | 2.00 | 85%min | all pass | all pass | ||||||||

| 12 | 1.70 | 97%min | 85%min | 5%max | all pass | |||||||

| 14 | 1.40 | 97%min | 85%min | 5%max | all pass | |||||||

| 16 | 1.18 | 97%min | 85%min | 5%max | all pass | |||||||

| 18 | 1.00 | 96%min | 85%min | 5%max | all pass | |||||||

| 20 | 0.850 | 96%min | 85%min | 10%max | all pass | |||||||

| 25 | 0.710 | 96%min | 85%min | 10%max | ||||||||

| 30 | 0.600 | 96%min | 85%min | all pass | ||||||||

| 35 | 0.500 | 97%min | 85%min | 10%max | ||||||||

| 40 | 0.425 | 97%min | all pass | |||||||||

| 45 | 0.355 | 80%min | 10%max | |||||||||

| 50 | 0.300 | 90%min | ||||||||||

| 80 | 0.180 | 80%min | ||||||||||

| 120 | 0.125 | 90%min | ||||||||||

| 200 | 0.075 | |||||||||||

| 325 | 0.045 | |||||||||||

| SAE | S-780 | S-660 | S-550 | S-460 | S-390 | S-330 | S-280 | S-230 | S-170 | S-110 | S-70 | |

Product Applications

In shipyards, steel shots are widely used for surface and secondary sandblasting of hulls, ensuring effective rust removal and cleaning. They are also applied in the pretreatment lines for hull steel plates.

Section steel and plate accessories in steel structures are treated with through-type shot blasting machines, which focus on achieving the required surface cleanliness and roughness. This preparation ensures better adhesion for subsequent processes such as painting. For customers, selecting high-quality and cost-effective steel shots is essential to reduce overall production costs and minimize shot loss during sandblasting.

Rust Removal Applications: Includes shot blasting, shot peening, rust removal for castings, forgings, steel plates, H-beams, and steel structures.

Shot Blasting Applications: Applied to section steel, ship plates, steel plates, and general steel shot blasting.

Pretreatment Applications: Covers coating pretreatment, surface pretreatment, ship plate pretreatment, and steel structure pretreatment.